What are Telescopic Hydraulic Cylinders

Introduction

In the dynamic world of hydraulics, telescopic hydraulic cylinders are a unique design in engineering. The capabilities of these hydraulic cylinders make them indispensable in numerous applications where space is limited and the range of extension is large. This article will delve into the intricacies of these hydraulic cylinders, shedding light on their operating principles, advantages, and basic considerations for selection and maintenance.

Design and Functionality

Telescopic hydraulic cylinder, often likened to the optical telescopes for their extendable design, are masterpieces of engineering efficiency and compact power. At their core, these cylinders are constructed from a series of steel or aluminum tubes, known as stages, which neatly nest inside one another. This unique structure is pivotal to their functionality and sets them apart from standard cylinders.

Structure of Telescopic Hydraulic Cylinder

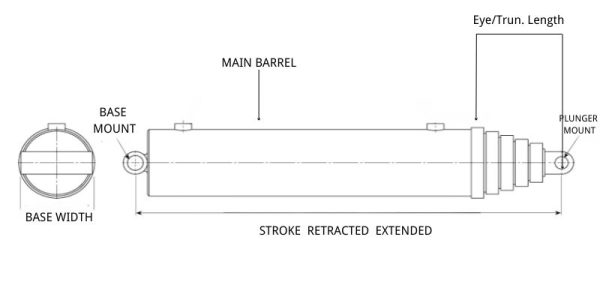

A telescopic cylinder’s anatomy is akin to a set of concentric tubes, each progressively smaller and fitting inside the next. The largest tube, or the barrel, houses the remaining stages, which are each successively smaller and capable of sliding into the larger stage before it. These stages are connected and sealed with durable materials, ensuring airtight operation and minimal friction. The base of the cylinder typically houses the hydraulic fluid port, which controls the movement of the stages.

Differentiating Telescopic and Standard Cylinders

The key difference between telescopic and standard hydraulic cylinders lies in their stroke length relative to their size. A standard hydraulic cylinder’s stroke length is directly tied to the physical length of the cylinder. This means that for a long stroke, the cylinder itself must be long when fully retracted. Telescopic cylinders, on the other hand, are designed to extend much further than their retracted length would suggest. This makes them ideal for applications where space is limited but a long stroke is required.

Working Principle of Telescopic Hydraulic Cylinder

Telescopic cylinders operate on the fundamental principle of hydraulic fluid pressure. When hydraulic fluid is pumped into the cylinder, it exerts pressure on the innermost stage, causing it to extend. As this stage reaches its full extension, the increased pressure then begins to extend the next stage, and this process continues until all stages are fully extended. The retraction process typically occurs in the reverse order, often assisted by gravity or external forces, depending on the design of the cylinder (single-acting or double-acting).

Basic design types of telescopic cylinders

Hydraulic telescopic cylinders are ingeniously designed to offer versatility and efficiency, adapting to diverse requirements in industrial applications. Primarily, there are three basic design types of telescopic cylinders: single-acting, double-acting, and combination types. Each design has its unique characteristics and applications, making them suitable for different operational needs.

Single-Acting Telescopic Cylinders

Single-acting telescopic cylinders are the simplest form of telescopic cylinders. In these cylinders, hydraulic fluid pressure is used only for extending the cylinder. The retraction process is typically not powered by hydraulic pressure but rather relies on external forces such as gravity, mechanical springs, or load weight. This design is simpler and often more cost-effective than its double-acting counterpart.

In single-acting cylinders, fluid is pumped into the cylinder, pushing the stages to extend sequentially. Once the work is done, the fluid is released, and the cylinder retracts either under its own weight or with the help of external forces. These cylinders are widely used in applications where the retracting force is readily available and consistent, such as dump trucks, where gravity assists in the retraction of the cylinder as the truck bed is lowered.

Double-Acting Telescopic Cylinders

Double-acting telescopic cylinders are more complex and offer greater control. In these cylinders, hydraulic fluid is used to control both the extension and retraction of the cylinder stages. This dual functionality is achieved by having two hydraulic fluid ports, one for extension and one for retraction.

The ability to control both the extension and retraction phases makes double-acting cylinders highly versatile and precise. They are ideal for applications requiring more exact control of movement and for situations where external forces are not sufficient or reliable for retraction. Double-acting telescopic cylinders are commonly found in industrial machinery, manufacturing equipment, and complex hydraulic systems requiring precise motion control.

Combination Telescopic Cylinders

Combination telescopic cylinders incorporate features of both single and double-acting designs. They can be customized to suit specific requirements where certain stages of the cylinder are double-acting and others are single-acting. This design flexibility allows for a tailored approach to match the unique demands of various applications.

Combination cylinders are often used in specialized equipment where the initial extension requires precise control (double-acting function), but the final stages of extension or retraction can be managed with external forces (single-acting function). This design offers a balance between control and simplicity, making it suitable for a wide range of applications with specific operational needs.

Applications of Hydraulic Telescopic Cylinders

Telescopic cylinders are pivotal in numerous industries, demonstrating their versatility and efficiency in a variety of challenging environments. Their unique ability to provide a long stroke in a compact form when retracted makes them indispensable in many applications.

Construction

In the construction industry, telescopic cylinders are extensively used in machinery like excavators and backhoes. For instance, they are employed in the boom of an excavator, allowing it to reach far and dig deep while maintaining stability and compactness when not in use. A case in point is the deployment of telescopic cylinders in large-scale construction projects where their extended reach and strength enable heavy lifting and precise movements of earth and materials.

Waste Management

In waste management, especially in garbage trucks, telescopic cylinders play a crucial role. They are used to operate the compacting mechanism in garbage trucks. As waste is collected, the telescopic cylinder extends to compress the waste, maximizing the truck’s carrying capacity. This efficient use of space means fewer trips to the dumpsite, reducing operational costs and environmental impact.

Agriculture

In the agricultural sector, hydraulic telescopic cylinders are found in equipment like telehandlers and tractors. They enable machinery to perform a variety of tasks, from lifting heavy loads to precise positioning of implements. For example, a farmer using a telehandler with a telescopic cylinder can stack large hay bales efficiently, illustrating the cylinder’s ability to handle heavy loads with ease and precision.

Advantages of hydraulic telescopic cylinders

Hydraulic telescopic cylinders stand out in the world of hydraulics for their unique design and functionality, offering a set of advantages that distinguish them from other types of cylinders. These advantages, particularly their space efficiency and extended reach capabilities, make them an ideal choice in numerous applications where traditional hydraulic cylinders may not suffice.

Identifying Worn or Damaged Components:

Space Efficiency

One of the most significant advantages of telescopic cylinders is their compact design. Unlike standard hydraulic cylinders, where the length of the cylinder is roughly equal to the stroke length, telescopic cylinders provide a much longer stroke while maintaining a much shorter retracted length. This space-saving feature is particularly beneficial in applications where space constraints are a critical factor.

The nested, multi-stage design of telescopic cylinders means they can achieve the same or greater stroke lengths as standard cylinders but occupy a fraction of the space when retracted. This makes them highly suitable for mobile applications where size and weight are limiting factors.

Extended Reach Capabilities

Hydraulic telescopic cylinders offer unparalleled extended reach capabilities. Their multi-stage design allows them to extend much further than a standard cylinder of the same retracted length. This feature is essential in applications where reaching out over long distances or heights is necessary.

In scenarios where a long stroke is required but the installation space is limited, such as in underground mining machinery, the extended reach of telescopic cylinders becomes an indispensable feature. This capability not only enhances the functionality of the equipment but also increases operational efficiency by reducing the need for multiple pieces of equipment.

Selection Criteria and Considerations

Selecting the right telescopic hydraulic cylinder for a specific application requires careful consideration of several key factors. This ensures optimal performance, longevity, and safety of the equipment.

Size and Stroke Length

The size and stroke length are paramount in choosing a telescopic cylinder. It’s essential to determine the space available for the cylinder when retracted and the required extension length. The cylinder should fit comfortably in the allocated space while retracted and achieve the desired stroke length when extended. In applications with limited space, telescopic cylinders offer an advantage over standard cylinders due to their compact design.

Material and Construction Quality

The material of the telescopic cylinder impacts its durability and suitability for specific environments. Common materials include steel and aluminum, each with its advantages. Steel cylinders are known for their strength and durability, making them suitable for heavy-duty applications. In contrast, aluminum cylinders are lighter and resistant to corrosion, ideal for applications where weight and environmental factors are a concern, such as in marine applications or where corrosion is a risk.

Load Capacity

Load capacity is a critical factor. The cylinder must be capable of handling the maximum load expected in the application. Overloading a cylinder can lead to mechanical failure, posing safety risks. It’s important to assess the maximum load the cylinder will need to support and select a cylinder with an appropriate safety margin above this figure.

Mounting Configuration

The mounting configuration of the cylinder should align with the application’s mechanical and spatial constraints. Different mounting options offer varying degrees of flexibility, stability, and ease of installation. Common mounting styles include flange, foot, and trunnion mounts. The choice depends on the application’s requirements for cylinder movement and alignment.

Operating Pressure and Temperature

The operating pressure range of the cylinder should match the hydraulic system’s capabilities. Additionally, consider the temperature range the cylinder will be exposed to. Extreme temperatures can affect the performance and lifespan of the hydraulic seals and fluid. Selecting a cylinder designed for the specific temperature and pressure conditions it will encounter is crucial.

Special Design Considerations

Depending on the application, special design considerations such as cylinder speed, cushioning at the end of the stroke, and the need for integrated valves or sensors may be important. For instance, in precision applications, cylinders with integrated position sensors may be required.

Maintenance and Troubleshooting

Proper maintenance and timely troubleshooting are vital for the longevity and efficient operation of telescopic hydraulic cylinder. Regular maintenance ensures that the cylinders perform at their best, while effective troubleshooting methods can save time and resources by quickly addressing common issues. Here are some essential tips and techniques:

Regular Maintenance Tips

- Routine Inspection: Regularly inspect the telescopic hydraulic cylinder for signs of wear, corrosion, or damage. Pay special attention to the seals, as they are crucial for preventing leaks.

- Lubrication: Ensure that all moving parts, particularly the stages of the cylinder, are adequately lubricated. This reduces friction, wear, and the risk of seizing.

- Cleanliness: Keep the cylinder and surrounding area clean. Dirt and debris can cause damage to the cylinder, especially when they enter the sealing areas.

- Hydraulic Fluid Check: Regularly check the hydraulic fluid level and quality. Contaminated or old fluid can lead to performance issues and damage to the cylinder.

- Leak Detection: Regularly check for leaks in the hydraulic system. Even small leaks can lead to a loss of pressure and reduced efficiency.

- Seal Integrity: Inspect the integrity of the seals periodically. Worn or damaged seals are a common cause of cylinder failure and should be replaced promptly.

Troubleshooting Common Issues

- Cylinder Does Not Extend Fully: If the cylinder does not extend fully, check for low hydraulic fluid levels, air in the system, or blockages in the hydraulic lines. Also, inspect the internal stages for mechanical damage.

- Slow or Jerky Operation: This issue can be caused by air in the system, low fluid levels, or contaminated hydraulic fluid. Bleed the system of air and ensure the fluid is at the correct level and clean.

- Leaks: Leaks around the seals or fittings can cause a drop in pressure. Tighten fittings and replace worn or damaged seals.

- Unusual Noises: Noises such as banging or knocking can indicate air in the system or mechanical damage within the cylinder. Bleed the system and inspect the cylinder for internal damage.

- Uneven Movement: If the cylinder extends or retracts unevenly, check for bent stages, damaged seals, or uneven load distribution.

Conclusion

Understanding the advantages, applications, and maintenance needs of telescopic hydraulic cylinders empowers users to make informed decisions, optimize their use, and maintain them effectively. This knowledge is key to leveraging their full potential, ensuring that these powerful tools contribute significantly to the efficiency and success of various industrial operations.