Key Tips for Hydraulic Cylinder Identification

The identification of hydraulic cylinders is more than just a technical requirement; it is the cornerstone of ensuring operational efficiency, safety and the longevity of machinery. This blog post delves into the nuances of hydraulic cylinder identification, providing important insights and practical tips for distinguishing hydraulic cylinders.

Understanding Hydraulic Cylinders

Basics of Hydraulic Cylinders

Hydraulic cylinder is a mechanical actuator that provides unidirectional force through a unidirectional stroke. It harnesses the power of pressurized hydraulic fluid to enable machinery to lift, push, pull, or press with significant force.

These cylinders come in various types, each tailored to different applications and load requirements. The most common types include:

Tie-Rod Cylinders: Characterized by their strong tie-rods, which secure the cylinder ends and bear most of the load. They are widely used in industrial machinery due to their durability and ease of maintenance.

Welded Rod Cylinders: Known for their robust construction with no tie-rods, these cylinders are typically used in heavy-duty applications where space is limited and higher operating pressures are required.

Telescopic Cylinders: These are multi-stage units that extend much further than a standard cylinder, perfect for applications requiring a long extendable reach, such as in dump trucks and material handling.

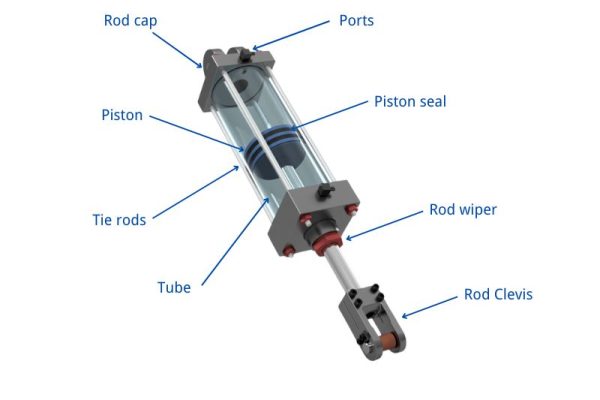

Components of Hydraulic Cylinders

Understanding the components of hydraulic cylinders is key to identifying and maintaining them effectively. The main parts include:

Barrel: The cylinder barrel houses the piston and the fluid under pressure. It is typically made of hardened steel to withstand the high pressures of hydraulic systems.

Piston: Positioned inside the barrel, the piston divides the cylinder into two chambers and moves back and forth under hydraulic pressure.

Rod: The rod extends from the piston and protrudes outside the cylinder, converting the fluid power into mechanical force.

End Caps: These are located at both ends of the barrel, sealing the cylinder and providing mounting provisions.

Seals: Essential for maintaining pressure and preventing fluid leaks, seals are found throughout the cylinder, particularly around the piston and rod.

These components work in unison to create the powerful and controlled movement that hydraulic cylinders are known for, making them indispensable in various mechanical applications.

Key Identification Techniques

Reading and Understanding Cylinder Markings

Decoding the markings on a hydraulic cylinder is an essential skill for anyone involved in their maintenance, repair, or even purchase. These markings, often etched or stamped on the cylinder, are akin to an identity card, providing a wealth of information crucial for proper handling and servicing. Let’s delve deeper into understanding these markings:

Part Numbers:

These alphanumeric codes are perhaps the most direct way to identify a hydraulic cylinder. Manufacturers assign these unique identifiers, often encapsulating information about the cylinder’s design and specifications. For instance, in a part number like “HC-1020,” ‘HC’ could signify the type or series of the cylinder, and ‘1020’ could represent specific features such as size or capacity. Understanding a manufacturer’s part numbering system can reveal information about the cylinder’s construction material, type of mount, bore size, stroke length, and rod diameter. This knowledge is invaluable for sourcing replacement parts or understanding the cylinder’s capabilities.

Serial Numbers:

The serial number of a hydraulic cylinder is its unique fingerprint. No two cylinders, even of the same model, will share the same serial number. This number is critical for tracing the cylinder’s history. By referencing the serial number, one can ascertain the manufacturing date, track any past maintenance or repairs, and validate warranty claims. In the event of a recall or known issue with a particular batch, the serial number helps in quickly identifying affected units. It’s a key tool in maintaining the safety and integrity of hydraulic systems.

Additional details often found on hydraulic cylinders can be incredibly informative. For example:

- Pressure Ratings: These figures are crucial for safety and operational purposes, indicating the maximum pressure the cylinder can safely withstand. Using a cylinder beyond its rated pressure can lead to failure and accidents.

- Bore Size and Stroke Length: These dimensions are central to understanding the force a cylinder can exert and how far the piston can travel. They are vital for matching the cylinder to the required application.

- Manufacturing Date: Knowing when a cylinder was made can help in determining its lifecycle stage, scheduling maintenance, or assessing wear and tear.

- Material Specifications: Some manufacturers also include information about the materials used, which can be important in applications where corrosion resistance or weight are factors.

Physical Inspection Methods

Physical inspection of hydraulic cylinders is a critical aspect of their maintenance and identification. A thorough inspection not only helps in identifying the type and condition of the cylinder but also in preventing potential failures. Here’s a detailed guide on conducting a physical inspection:

Visual Inspection:

- Start with a Surface Check: Look over the entire cylinder for any visible signs of damage. This includes checking for scratches, dents, or rust on the cylinder’s body. Such signs can be indicative of rough handling or exposure to harsh conditions.

- Corrosion Inspection: Pay close attention to any signs of corrosion, especially in cylinders used in environments with moisture or corrosive chemicals. Corrosion can compromise the structural integrity of the cylinder.

Dimensional Check:

- Measure Key Dimensions: Using precise measuring tools, determine the bore diameter, rod diameter, and the stroke length of the cylinder. These dimensions are vital in identifying the cylinder’s specifications and its suitability for specific applications.

- Record Your Findings: Keep a record of these dimensions for future reference, especially when ordering spare parts or comparing with manufacturer specifications.

Check for Wear and Tear:

- Rod Inspection: Examine the cylinder rod for any pitting, scoring, or uneven wear. Damage to the rod can impair the cylinder’s functionality and lead to seal damage.

- Surface Integrity: Ensure that the rod’s surface is smooth and free of any irregularities that could compromise the seal or the cylinder’s performance.

Inspect Seals:

- Seal Condition: Check the seals for any visible signs of wear, such as cracking, hardening, or extrusion. Damaged seals are a common cause of cylinder leaks and inefficiencies.

- Seal Replacement: Consider the age and condition of the seals. Even if they are not visibly damaged, old seals may warrant replacement as a preventive measure.

Joint and Connection Points:

- Mounting Points: Inspect all mounting points and joints for looseness or misalignment. Loose connections can lead to instability and increased wear.

- Ensure Secure Connections: Tighten any loose bolts or fasteners and ensure that all connection points are in good condition.

Functionality Test:

- Operational Check: If feasible, operate the cylinder through its entire range of motion. Watch for any signs of irregular movement or performance issues.

- Smooth Operation: The cylinder should move smoothly without any jerks or hesitation. Any abnormalities in movement could indicate internal issues.

Advanced Identification Strategies

In the era of digital transformation, the hydraulic cylinder industry is not left behind. The utilization of modern technology for the identification of hydraulic cylinders offers a range of sophisticated tools that streamline the process, making it more efficient and accurate. Let’s explore these technological advancements in detail:

Identification Software

- Purpose-Built Solutions: Software specifically designed for hydraulic systems can significantly simplify the identification process. These programs often include features to input and match cylinder specifications such as dimensions, pressure ratings, and manufacturer codes against a comprehensive database.

- Extensive Databases: These databases can encompass a wide variety of cylinder models and types, offering a one-stop solution for identifying and cross-referencing cylinder specifications.

Mobile Applications

- Convenience of Mobility: With the advent of mobile technology, several applications have been developed that allow users to identify hydraulic cylinders on the go.

- Features and Functionality: These apps might include capabilities like image recognition, where a user can take a photo of the cylinder, and the app will analyze and provide relevant details about the cylinder’s type and specifications.

RFID Technology

- Tagging for Efficiency: RFID tags attached to hydraulic cylinders can store extensive data about the cylinder, such as its manufacturing details, specifications, and maintenance history.

- Quick Data Retrieval: Using an RFID scanner, this information can be accessed swiftly, greatly aiding in quick identification and reducing the time spent on manual checks.

3D Scanning Tools

- Accurate Digital Replication: Advanced 3D scanning technology can create accurate digital models of hydraulic cylinders. This can be particularly useful in complex systems where precise dimensions are critical.

- Wear Pattern Analysis: These digital models allow for detailed analysis, such as assessing wear patterns, which can be crucial for predicting maintenance needs or identifying potential issues.

Predictive Maintenance Software

- AI-Driven Insights: By harnessing the power of AI and machine learning, predictive maintenance software can analyze historical data and real-time performance of hydraulic cylinders.

- Proactive Maintenance Approach: This analysis helps in predicting potential failures or maintenance requirements, enabling a shift from reactive to proactive maintenance strategies.

Advantages of Adopting Technology in Cylinder Identification

Enhanced Accuracy: Digital tools minimize human error in the identification process, ensuring more accurate results.

Time Efficiency: These technologies significantly speed up the identification process, a crucial factor in time-sensitive maintenance situations.

Comprehensive Data Access: Access to extensive databases and historical information aids in making well-informed decisions.

Predictive Insights: Advanced software can forecast potential issues, allowing for proactive maintenance and reducing downtime.

Identification Errors and Their Consequences

Misidentification of hydraulic cylinders can lead to a range of serious consequences, impacting both operational efficiency and safety. Here are some real-world examples and their impacts:

Using Incorrect Cylinder Size

Example: A construction company mistakenly installed a hydraulic cylinder with a smaller bore size than required for their heavy equipment. This led to insufficient force, causing the machinery to malfunction under load.

Impact: The error resulted in a significant delay in project completion and increased costs due to equipment downtime and repairs.

Mismatched Pressure Ratings:

Example: In a manufacturing plant, a cylinder with a lower pressure rating than necessary was installed in a high-pressure application.

Impact: The cylinder failed, causing a halt in production and posing serious safety risks to the workers due to the sudden release of hydraulic fluid under high pressure.

Inadequate Material Selection:

Example: A cylinder not suited for corrosive environments was used in a chemical processing facility.

Impact: Corrosion led to the premature failure of the cylinder, necessitating costly replacements and posing environmental hazards.

Tips to Avoid Common Pitfalls

Properly identifying hydraulic cylinders is vital for maintaining system integrity and safety. Here’s an expanded look at the practical tips and a checklist to prevent common identification errors:

Always Refer to Manufacturer Specifications:

- In-Depth Verification: It’s essential to not only match part numbers but also delve into the detailed specifications provided by the manufacturer. This includes checking the compatibility of the cylinder with specific fluids, temperature ranges, and pressure capabilities.

- Update on Changes: Stay informed about any updates or changes in manufacturer specifications, as these could affect the suitability of the cylinder for certain applications.

Understand the Application Requirements:

- Load and Pressure Assessment: Thoroughly evaluate the mechanical and hydraulic load requirements, as well as the operating pressure range of the system. Ensure the selected cylinder can handle these conditions without risk of failure.

- Environmental Considerations: Consider factors such as exposure to corrosive substances, extreme temperatures, or high levels of vibration, which could necessitate specialized cylinder types.

Regular Training and Awareness:

- Ongoing Education: Continuously educate the personnel involved in cylinder selection and maintenance on the latest trends, technologies, and standards in hydraulic cylinder identification.

- Workshops and Seminars: Encourage attendance at relevant workshops and industry seminars to stay abreast of new developments and best practices in the field.

Use Digital Tools for Verification:

- Maximizing Accuracy: Utilize identification software and mobile applications to cross-reference and verify cylinder specifications. These tools can greatly reduce the risk of human error in the identification process.

- Real-Time Updates: Take advantage of software that provides real-time updates on cylinder specifications and compatibility, ensuring the most current information is used for identification.

- Implement a Double-Check System:

- Peer Review: Establish a protocol where another qualified individual, such as a hydraulic engineer or maintenance supervisor, reviews the cylinder specifications before finalizing the selection and installation. This can catch errors that might have been overlooked initially.

Maintain Detailed Records:

- Comprehensive Logging: Keep an exhaustive log of all hydraulic cylinders in use, including their part numbers, installation dates, maintenance history, and any issues encountered. This log can be invaluable for troubleshooting and ensuring timely maintenance.

- Digital Record-Keeping: Consider using a digital system for record-keeping, which can simplify tracking and updating cylinder information.

Remember, the key to successful hydraulic cylinder identification lies in a combination of detailed knowledge, vigilant inspection, and leveraging the right tools. By implementing the tips and best practices outlined in this guide, professionals in the field can ensure the reliability and safety of their hydraulic systems, ultimately contributing to the smooth operation and success of their respective industries.

Conclusion

In closing, may this guide serve as a valuable resource, empowering you with the knowledge and tools to master the art of hydraulic cylinder identification. Here’s to the safe and efficient operation of your hydraulic systems!