The Comprehensive Guide to Hydraulic Cylinders

Introduction

Hydraulic cylinders are precision mechanical devices that convert hydraulic energy into linear motion. They are an important hydraulic accessory behind the movement of various equipment and perform all functions from heavy lifting to precision movement of machinery. This guide will explore hydraulic cylinder in depth by dissecting their components, types, and operating principles.

Understanding Hydraulic Cylinder

Basic Components and Structure

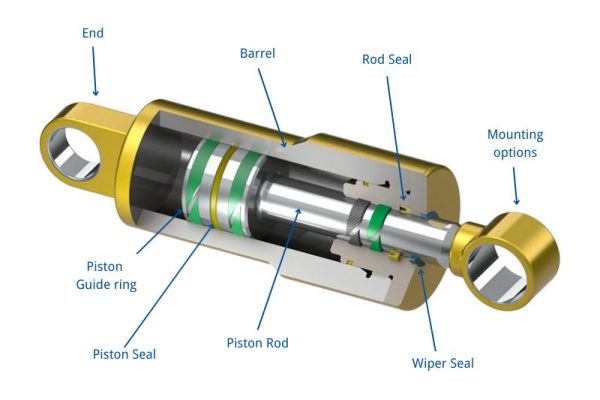

Hydraulic cylinder may seem like simple, but they are complex assemblies with several crucial parts, each serving a specific function.

Cylinder Barrel

The cylinder barrel is the main body of the hydraulic cylinder and houses the piston and the hydraulic fluid. It’s typically made from robust materials like steel to withstand high pressure and prevent leakage.

Piston and Piston Rod

The piston, attached to a piston rod, moves back and forth within the cylinder barrel. This movement is what translates the hydraulic fluid’s energy into mechanical force. The piston rod extends outside the cylinder and connects to the machinery that needs to move.

Cylinder Head and Base

These are the caps at either end of the cylinder barrel. The head is where the piston rod exits the cylinder, and the base is usually opposite to it. Both are designed to seal the pressure inside and provide mounting points for the cylinder.

Seal

Seals are vital for maintaining the hydraulic cylinder’s integrity. They prevent the hydraulic fluid from leaking and ensure that the pressure is contained within the cylinder. Seals need to be durable to withstand the pressure and motion within the cylinder.

Seal Gland

The seal gland, or gland nut, is the part of the cylinder where the seal is housed. It’s typically located in the cylinder head and plays a critical role in maintaining the seal’s position and effectiveness.

Clevis

The clevis is an essential component often associated with hydraulic cylinder, especially when discussing the various types of mounting options and connections between the cylinder and the machinery it operates. It plays a significant role in ensuring efficient and safe operation.

A clevis is a U-shaped or forked metal fitting that attaches to the rod end or base of a hydraulic cylinder. It usually consists of two parallel arms with a hole at the end of each arm, through which a pin or bolt passes. The primary function of a clevis is to provide a pivot point or a secure attachment between the hydraulic cylinder and the machine part it is pushing or pulling. This attachment allows for a certain degree of angular movement and alignment flexibility, accommodating for slight misalignments and changes in the angle of force application.

In addition to the clevis, hydraulic cylinder offers a variety of mounting options to accommodate different applications and ensure optimal performance. Each mounting type offers its own set of advantages and considerations. Here’s an overview of other common mounting options:

Flange Mounts: Flange mounts are rigid and robust mounting options located at one or both ends of the cylinder. They consist of a flange attached to the cylinder’s head or cap, which is then bolted to the machine structure.

Trunnion Mounts: Trunnion mounts involve cylindrical protrusions (trunnions) located at the mid-point or ends of the cylinder. These trunnions pivot within their mounts, allowing the cylinder to swing.

Foot Mounts: Foot mounts are brackets or flanges attached to the cylinder’s body, allowing it to rest and be bolted onto a flat surface, typically at the base.

Rod Eye/Rod Clevis: Attachments at the end of the piston rod providing a pivot point for connection to the load. The rod eye is a circular attachment, while the rod clevis is U-shaped.

Spherical Bearings: Used at mounting points, spherical bearings allow for rotation and angular alignment. They are often used in conjunction with other mounts like rod eyes or clevis.

Side Lug Mounts: Projections with holes on the cylinder body’s sides allow it to be bolted directly to a surface or structure.

Centerline Lug Mounts: Similar to side lugs but located along the cylinder’s centerline, these mounts help absorb forces directly in line with the cylinder’s center.

Types of Hydraulic Cylinders

The functionality and design of hydraulic cylinder can vary based on the requirements of the application. Here are some common types:

Single-Acting and Double-Acting Hydraulic Cylinder

Single-Acting Hydraulic Cylinder: These cylinders apply force in one direction, typically using a spring or the load itself to return to the original position. They are simpler in design and often used in tools and applications where one-directional force is sufficient.

Double-Acting Hydraulic Cylinder: In contrast, double-acting cylinders can apply force in both directions, using hydraulic power to extend and retract the piston. This allows for more control and is useful in applications where retraction and extension both need to be controlled, such as in industrial machinery.

Telescopic Hydraulic Cylinder

These cylinders have sections that extend like the segments of a telescope. They’re used when a long stroke is needed from a compact cylinder. Often found in applications like dump trucks and heavy load lifting, telescopic cylinders provide the extended reach without needing the full-length space when retracted.

Tie Rod and Welded Hydraulic Cylinder

Hydraulic Tie Rod Cylinder: Tie rod cylinders use external rods to secure the end caps to the barrel and are typically easier to service and maintain. The tie rods bear the tension forces during operation, making it possible to dismantle the cylinder for repairs or maintenance.

Hydraulic Welded Cylinder: Welded cylinders have end caps welded directly to the barrel and are more compact and robust. The lack of tie rods allows for a sleeker design that’s often preferred in mobile applications. However, they are generally not as easy to service as tie rod cylinders.

Plunger Hydraulic Cylinder

Also known as ram cylinders, these use a solid piston (plunger) that moves within a sleeve or tube. They’re typically used for pushing rather than pulling and are known for their high force capabilities. The design is generally simpler, with the large surface area of the plunger providing significant pushing power. They are commonly used in applications such as hydraulic presses and jacks.

Principles of Hydraulic Cylinder Operation

To understand how does a hydraulic cylinder work, we must grasp a few fundamental principles:

Pascal’s Law Principle: This law states that a change in pressure at any point in a confined fluid is transmitted undiminished throughout the fluid. In the context of a hydraulic cylinder, this means that the pressure applied to the fluid is transferred directly to the piston, creating movement.

Hydraulic Fluid Dynamics: The hydraulic fluid is the lifeblood of the cylinder. It must be incompressible and have properties that maintain its performance over a wide temperature range. The fluid’s movement and pressure within the cylinder are what create the force and movement of the piston.

Role of Seals and Bearings: Seals prevent the hydraulic fluid from leaking, while bearings guide and support the piston rod as it moves. Both are crucial for the smooth and efficient operation of the cylinder.

Hydraulic Cylinder Applications

Hydraulic cylinder is a key component in many industries, powering most of the machinery we use every day. Let’s explore some of their most common applications in a variety of industries:

Construction Equipment

Hydraulic cylinder is almost ubiquitous in the construction and earthmoving field. They are the power behind some of the most powerful and basic equipment in the industry.

- Excavators: Hydraulic cylinder in excavators provide the precise control needed for digging and material handling. They control the boom, arm and bucket, providing the lifting and digging forces needed.

- Bulldozers: Bulldozers have blades and openers controlled by hydraulic cylinder that push large amounts of dirt, sand and gravel.

- Cranes: Hydraulic cylinder in cranes lift heavy loads and extend booms, combining power with precise control.

Automotive

The automotive industry relies heavily on hydraulic cylinder for both manufacturing and maintenance.

- Vehicle Assembly: From pressing parts to lifting vehicles during assembly, hydraulic cylinder is a integral to automotive manufacturing.

- Maintenance Equipment: Hydraulic lifts used in car repairs to elevate vehicles are powered by hydraulic cylinder, providing safety and stability for under-vehicle work.

Agriculture

In the rugged world of agriculture and forestry, cylinders stand up to some of the toughest tasks.

Tractors: Almost every function that involves movement in a tractor, from the lifting of attachments to steering, relies on hydraulic cylinder.

Harvesting Equipment: Machines like combines and harvesters use hydraulic cylinder for various functions, including cutting and gathering crops.

Felling Machines: In forestry, those components provide the force necessary to power felling machines and other logging equipment.

Industrial Machinery and Manufacturing

In the manufacturing sector, hydraulic cylinders are key components in a wide array of machinery, ensuring operations run smoothly and efficiently.

- Assembly Lines: They are used to lift, press, and move parts along the production line, providing both the precision and force needed in manufacturing.

- Presses: Hydraulic cylinder in presses exert the enormous force required for molding, shaping, or cutting materials.

- Conveyor Systems: They are often used to control the movement and loading mechanisms in conveyor systems, crucial for mass production facilities.

Understanding Hydraulic Cylinder in Detail

When researching hydraulic cylinder in depth, it is vital to understand their specifications and requirements. These factors are essential to ensure that the hydraulic cylinder you select or design is perfectly suited for its intended application. Let’s take a closer look at these specifications:

Specifications and Requirements

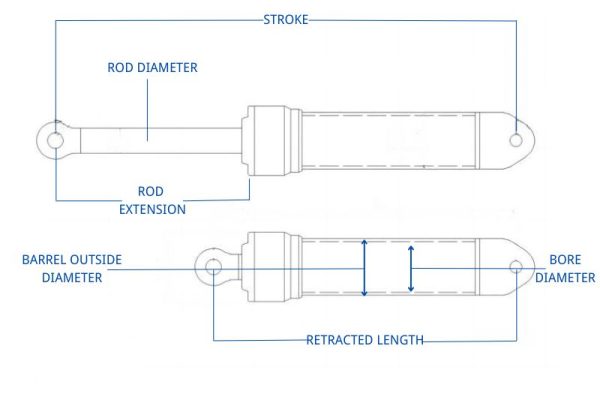

Bore Size

Determining the Power and Capacity: The bore size, or the diameter of the cylinder’s inner chamber, is a critical factor in determining its power and capacity. A larger bore can handle more force due to the increased area upon which the hydraulic fluid can act. This means that cylinders with larger bores can lift heavier loads.

Stroke Length

The Distance the Piston Can Travel: Stroke length refers to the maximum distance the piston can move within the cylinder, from fully retracted to fully extended. It’s a crucial specification as it determines how far the connected machinery or load can move.

Working Pressure

Maximum pressure that can be withstood: Working pressure is the maximum pressure that a hydraulic cylinder can safely handle. This specification is essential to ensure that cylinders operate safely and efficiently without risk of failure. Higher working pressures typically require stronger materials of construction and thicker internal walls to withstand the pressure. It is critical to select a cylinder that can withstand the maximum pressure of the hydraulic system.

Mounting Options

Mounting options are critical to how the cylinder is secured to the machine or structure. Common types of mounting include flange mounting, clevis mounting, trunnion mounting, and pedestal mounting, each with different benefits for different applications. And the choice of mounting method can affect the alignment of the cylinder, its ability to withstand loads, and the ease of installation and maintenance. It is important to consider the nature of the application and the forces involved to select the most appropriate mounting.

Materials

The materials used in constructing hydraulic cylinder significantly impact their performance, durability, and suitability for specific environments and applications. Let’s break down the common materials used and their implications:

Cylinder Material

The cylinder barrel must withstand high pressure and resist wear over time. Common materials include steel and stainless steel. Steel is known for its strength and durability, making it suitable for most applications. Stainless steel, while more expensive, offers enhanced corrosion resistance, making it ideal for harsh environments or applications involving corrosive fluids.

Piston Rod Material

The piston rod is subjected to significant stress and often exposure to external environments. Common materials include steel with hard chrome plating for increased wear resistance and corrosion protection. For more corrosive environments, stainless steel or even specialty coatings like nickel-chrome might be used.

Seal Type and Material

Seals are crucial in preventing fluid leakage and maintaining pressure. Common materials include polyurethane, nitrile rubber, and fluorocarbon. Each has different properties regarding temperature tolerance, wear resistance, and compatibility with different hydraulic fluids. The right seal type and material depend on the cylinder’s operating conditions, including pressure, temperature, and fluid type. A properly selected seal ensures optimal performance and longevity, reducing downtime and maintenance needs.

Custom vs Standard Hydraulic Cylinder

Choosing between custom and standard hydraulic cylinder depends on the specifics of the application and the requirements of the machinery or system.

Custom Hydraulic Cylinder

- Tailored Solutions: Custom cylinders are designed and built to meet the exact specifications of an application. This includes unique sizes, materials, mounts, and even special features like integrated sensors or unusual port placements.

- When to Choose Custom: Custom cylinders are ideal when standard options can’t meet the unique demands of your application, whether due to size constraints, unusual loads, or environmental conditions. They offer a perfect fit but typically come at a higher cost and longer lead times.

Standard Hydraulic Cylinder

- Off-the-Shelf Options: Standard cylinders come in predefined sizes and configurations. They are typically more cost-effective and readily available, making them suitable for more generic applications.

- When to Choose Standard: Standard cylinders are a good choice when the application’s demands fall within the capabilities of available models. They offer quicker availability and usually at a lower cost.

Maintenance and Troubleshooting

Proper maintenance and timely troubleshooting are critical to extending the life of cylinders and ensuring their efficient operation. Here’s how to keep your hydraulic fluid products in top shape and address common issues:

Routine Maintenance Tips

Keeping your hydraulic cylinder well-maintained not only prolongs their life but also enhances the safety and efficiency of your machinery.

- Regular Inspection: Frequently inspect your hydraulic cylinder for signs of wear, leaks, or damage. Pay special attention to the seals, piston rod, and barrel.

- Cleanliness: Keep the cylinders and surrounding area clean to prevent contamination of the system, which can lead to premature wear or failure.

- Lubrication: Ensure that all moving parts are adequately lubricated to minimize friction and wear.

- Fluid Checks: Regularly check the hydraulic fluid levels and quality. Contaminated or low fluid can lead to inefficient operation and damage.

- Alignment Checks: Ensure the cylinder and its load are correctly aligned to prevent undue stress and wear.

Identifying Common Issues

Leaks and Seal Failures

Causes: Seal wear, improper installation, or damage can lead to fluid leaks. Contamination and excessive pressure can also compromise seal integrity.

Solutions: Regularly inspect seals for wear and replace them as needed. Ensure seals are compatible with the hydraulic fluid used and the operating conditions of the cylinder.

Rod Bending and Misalignment

Causes: Overloading, improper mounting, or sudden impact can lead to rod bending. Misalignment can occur from incorrect installation or changes in the machinery’s structure.

Prevention and Correction: Ensure the cylinder is correctly mounted and the load is within its rated capacity. Use proper mounting options to accommodate minor alignment changes.

Pressure Problems

Understanding and Addressing Issues: Fluctuations or drops in hydraulic pressure can lead to inefficient cylinder operation or failure. These can be caused by leaks, pump issues, or blockages.

Solutions: Regularly check the hydraulic system’s pressure and inspect for any signs of leaks or blockages. Ensure the pump and other components are functioning correctly.

Repair and Replacement Options

When routine maintenance isn’t enough to keep your hydraulic cylinder operating correctly, it may be time to consider repair or replacement.

Repair: Many issues with hydraulic cylinder, such as seal replacement or rod straightening, can be repaired. Always turn to experienced technicians to ensure the repairs are done correctly.

Replacement: In cases where the cylinder is extensively damaged or outdated, replacing it might be more cost-effective and safer. Ensure the new cylinder meets or exceeds the specifications and requirements of your application.

Regular maintenance and early identification of issues are key to the longevity and efficiency of cylinders. By staying vigilant and addressing problems promptly, you can minimize downtime, reduce costs, and maintain operational safety and efficiency. When in doubt, consulting with a professional or the manufacturer can provide guidance tailored to your specific equipment and usage.

Advances in Hydraulic Cylinder Technology

The technology behind hydraulic cylinder is constantly evolving, with innovations aimed at enhancing performance, efficiency, and reliability. Understanding these advancements can help you make informed decisions and stay ahead in the industry. Here’s a look at the recent breakthroughs and future trends:

Innovations in Design and Materials

The design and materials used in a hydraulic cylinder has seen significant improvements, leading to enhanced performance and reliability.

- Composite Materials: New composite materials are being used to reduce weight and increase corrosion resistance, making cylinders suitable for harsher environments.

- Smart Cylinder Technology: Integration of sensors and IoT technology allows for real-time monitoring of cylinder performance, predictive maintenance, and enhanced control.

- Coatings and Surface Treatments: Advanced coatings and surface treatments for rods and seals are increasing the lifespan of cylinders by reducing wear and protecting against harsh substances.

Improvements in Efficiency and Performance

Modern hydraulic cylinder are becoming more powerful and efficient, thanks to various technological improvements.

- Higher Pressure Ratings: Developments in materials and design are allowing cylinders to operate safely at higher pressures, increasing their force output without needing a larger size.

- Energy-Efficient Designs: More efficient designs and better seal technology are reducing energy loss and operational costs.

- Variable Displacement Technology: This allows cylinders to adjust their volume and flow needs in real-time, optimizing performance and efficiency.

Future Trends and Potential Developments

As we look to the future, several trends and potential developments are poised to revolutionize the hydraulic cylinder industry.

- Self-Healing Materials: Research into self-healing materials could lead to seals and other components that automatically repair small cracks or wear, dramatically extending service life.

- Sustainability: There’s a growing emphasis on environmentally friendly hydraulic fluids and recyclable materials as industries become more conscious of their environmental impact.

- Miniaturization: Advances in materials and design might lead to smaller, more powerful cylinders for use in compact, space-sensitive applications.

Conclusion

Whether you’re an engineer, technician or industry expert, understanding hydraulic cylinder is critical to the growth of your industry. As technology continues to evolve, staying informed and adaptable will be key to realizing the full potential of your industry and maintaining a competitive edge. There is no doubt that hydraulic cylinder will continue to be the cornerstone of future industrial machinery and innovation. If you still have any questions about hydraulic cylinder, please consult with Topa and we will do our best to resolve your confusion!